Introduction

Load cells are essential components in various weighing and measurement systems, providing precise and reliable data for numerous applications. In this blog, we will explore the different types of load cells, their working principles, and applications. Keywords such as load cell types, load cell sensor, and compression load cell will be covered.

Types of Load Cells

1.Compression Load Cell

- Compression load cells are designed to measure the compressive force exerted on them. These are widely used in applications like weighbridges and industrial scales.

2.Strain Gauge Load Cell

- Strain gauge load cells are the most common type, using strain gauges to convert the force into an electrical signal. They are versatile and used in various industrial applications.

3.S Type Load Cell

- The S type load cell gets its name from its S-shaped design. It is used for both tension and compression applications and is known for its high precision.

4.Shear Beam Load Cell

Shear beam load cells are typically used in platform scales and process weighing applications. They provide high accuracy and reliability.

Load Cell Sensor and Calibration

The accuracy of load cells depends significantly on proper calibration. Load cell calibration involves adjusting the load cell to ensure its output corresponds accurately to the applied load. Regular calibration is crucial for maintaining the precision of any load cell sensor.

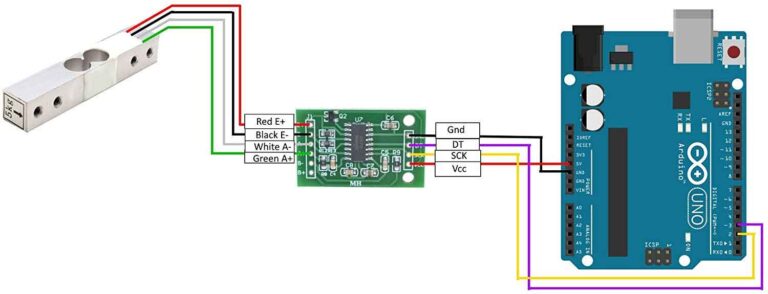

Wiring and Installation

Proper load cell wiring is essential for accurate measurements. Incorrect wiring can lead to errors and unreliable data. It is important to follow the manufacturer’s guidelines for wiring and installation to ensure optimal performance.

Understanding the different types of load cells and their applications helps in selecting the right sensor for your needs. For more information on high-quality load cells, visit our load cell factory and explore our wide range of products.